Why Are Food and Beverage Companies Using Bio-Based PET?

“Around the world, one million plastic drinking bottles are purchased every minute.”, according to the United Nations Environment Programme (UNEP). Further, as per National Geographic society, in just 60 years, a massive 8.3 billion tonnes of plastic have been produced around the world, most of which has become trash. Additionally, plastic production will double by 2050 from the 448 million tonnes created in 2015. This is already leading to the really big issue of plastic pollution, which is spreading to waterbodies and the atmosphere as well, apart from land.

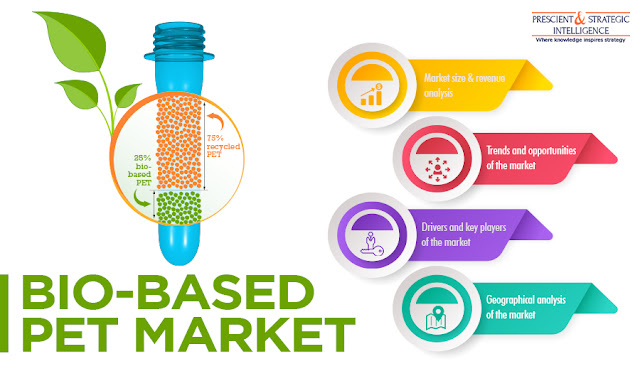

As per P&S Intelligence, the global outcry over this issue will take the bio-based polyethylene terephthalate (PET) market size from $3,917.4 million in 2017 to $8,682.6 million by 2023, at a 14.7% CAGR between 2018 and 2023. This will also be because of the high-volume consumption of PET, mostly in plastic bottles. Even though such bottles are intended to be for one-time use, they are made strong, which is why their plastic can take to 400 years to degrade on its own.

Apart from its durability, which restricts biodegradation, the depletion of oil and gas reserves is making petrochemical companies produce this material from bio-based feedstock. The raw materials for synthetic PET, terephthalic acid (TPA) and monoethylene glycol, are petroleum products; therefore, with the depleting oil and gas reserves because of overexploitation, their prices fluctuate. Therefore, petrochemical companies are now creating PET from only 70% synthetic TPA and 30% MEG derived from biological feedstock.

Currently, Asia-Pacific (APAC) is the largest bio-based PET market because of its huge consumer base. This creates a high demand for processed food and beverages, especially considering the rising disposable income of the people of regional developing countries. As a result, plastic consumption in the form of food packaging is escalating in the region, which is prompting food and beverage companies to use biodegradable PET and other plastics in their packaging material.

In other regions, the demand for this material is growing due to the implementation of stringent emission control laws, such as the Paris Agreement. It has been found that 6 kg of carbon dioxide are emitted by just 1 kg of plastic, which is why governments are forcing industrialists to increase their usage of bioplastics. Such measures are being complemented by those implemented to reduce the usage of fossil fuels altogether, which will further force manufacturers to source alternative raw materials for plastic production.

Hence, with the rising concerns regarding plastic pollution and greenhouse gas emissions, the usage of bio-based PET and other plastics will surge.

Comments

Post a Comment